Welcome to your premier destination for high-quality timing belts in Australia. As a division of Naismith Engineering & Manufacturing Co Pty Ltd, we bring over seven decades of experience and expertise to the power transmission industry. Our commitment to excellence and extensive range of products make us a leading supplier of timing belts and related equipment across the country.

Read More

Leading Supplier of Timing Belts in Australia

When it comes to timing belts Australia trusts, look no further than our comprehensive range of top-quality products. We've established ourselves as a go-to source for all your power transmission needs. Our expertise in timing belts is unmatched, backed by years of experience in manufacturing and importing mechanical power transmission products.

What sets us apart as a leading supplier of timing belts in Australia?

- Extensive Range: Our Melbourne warehouse, spanning nearly 2,400 square metres, houses over 30,000 stock items. This vast inventory ensures that we have the right timing belt for virtually any application.

- Quality Assurance: Quality is our watchword. We source our timing belts from Optibelt in Europe. Each product undergoes rigorous quality checks, with regular factory inspections carried out by our personnel to maintain the highest standards.

- Prompt Delivery: Most customer orders are dispatched on the same day they're placed. This efficiency minimizes downtime for your operations.

- Free Delivery: We offer free delivery on all orders over $75, providing added value to our customers.

- Expert Advice: Our team of knowledgeable professionals is always ready to assist you in selecting the right timing belt for your specific application.

Industrial Timing Belt

An industrial timing belt is a crucial component in many power transmission systems, providing precise synchronisation between rotating shafts. These belts are designed with teeth that fit into corresponding grooves on a pulley, ensuring positive drive with no slippage.

Key features of our industrial timing belts include:

- High Precision: Engineered to maintain exact synchronization, crucial for applications like camshaft timing in engines or coordinating movements in manufacturing equipment.

- Durability: Made from high-strength materials like polyurethane or neoprene with reinforcing fibres, these belts are built to withstand demanding industrial environments.

- Low Maintenance: Compared to chain drives, timing belts require no lubrication and operate more quietly.

- Efficiency: Timing belts offer high efficiency in power transmission, typically around 98%, helping to reduce energy costs.

- Versatility: Available in various sizes and tooth profiles to suit a wide range of industrial applications.

Whether you need a standard industrial timing belt or a custom solution, our extensive range and expertise ensure we can meet your specific requirements.

Check Out the Options Available

We offer a comprehensive range of timing belts to suit various industrial needs:

- Classical Timing Belts: These are the original timing belt design, featuring a trapezoidal tooth profile. They're suitable for many general industrial applications and are known for their reliability and cost-effectiveness.

- HTD Timing Belts: High Torque Drive (HTD) belts feature a curved tooth profile that allows for higher power transmission capabilities. They're ideal for high-torque, low-speed applications and offer improved load distribution compared to classical belts.

- Metric Timing Belts: These belts conform to metric standards and are widely used in European and Japanese machinery. They offer precise fitment and are available in various tooth profiles including trapezoidal and curvilinear.

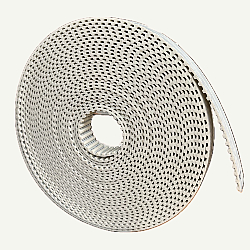

- Long Length Belting: For applications requiring extra-long belts, we offer long length timing belt material that can be cut and joined to create custom lengths. This is particularly useful for large machinery or unique design requirements.

Each type of timing belt has its own strengths, and our expert team is always ready to help you choose the best option for your needs

FAQs

What's the difference between timing belts and standard V-belts?

Timing belts have teeth that engage with grooves on a pulley, ensuring precise synchronisation. V-belts rely on friction and are more suitable for applications where exact timing isn't critical.

How do I determine the correct size of timing belt I need?

The size depends on factors like the pulley diameter, centre distance between pulleys, and the required gear ratio. Our team can help you calculate the correct size based on these factors.

Can timing belts be used in high-speed applications?

Yes, many timing belts are designed for high-speed applications. However, factors like heat generation and tooth engagement become crucial at high speeds.

How often should timing belts be replaced?

The replacement interval depends on the specific application, operating conditions, and manufacturer recommendations. Regular inspections can help determine when replacement is necessary.

Do you offer custom timing belts?

Yes, we can source or manufacture custom timing belts to meet specific requirements, including special materials or unique dimensions.